Introduction

A leading industrial manufacturer, located along the Houston Ship Channel, faced challenges associated with “Dust” (large particle, sand like texture) accumulation in their facility. The excess dust not only posed safety hazards but also affected the overall cleanliness of the premises. To address these issues, the company opted to integrate walk-behind and ride-on floor sweepers into their daily operations.

Challenges:

1. Dust Accumulation: The Facility’s production processes generated a significant amount of dust, leading to an unclean and potentially hazardous work environment.

2. Capital Constraints: Navigating the companies year end budgets and capital constraints, brought on by the past years economic turbulence, to provide an economically prudent solution.

3. Safety Concerns: The accumulated dust posed safety risks, increasing the likelihood of slips, trips, and falls among employees.

4. Indoor and Outdoor Impact: Dust particles not only affected the interior of the facility but also settled outside, impacting the surrounding environment.

Solution

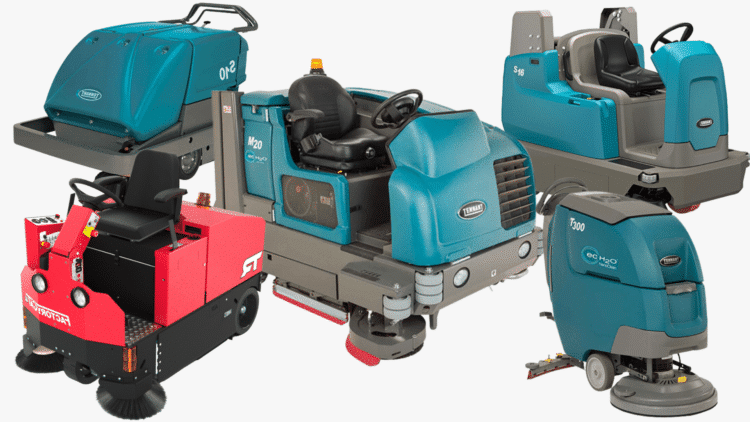

The Facility partnered with Allied Flooring Solutions to implement rentals of walk-behind and ride-on floor sweepers as a comprehensive solution. These machines were strategically deployed to address the various challenges faced by the manufacturing facility.

Implementation:

1. Strategic Solution: After performing a site visit, the correct machines were chosen to aptly control the dust and fit within budgetary constraints of the customer. The floor sweepers were strategically placed in high-dust areas, ensuring efficient coverage of the entire facility.

2. Regular Cleaning Schedule: A routine cleaning schedule was established to maintain cleanliness consistently, preventing the buildup of dust.

3. Outdoor Maintenance: The ride-on floor sweeper was used to clean the exterior surroundings, reducing the dispersion of dust outside the facility.

Results

1. Cleaner Facility: The implementation of floor sweepers led to a noticeable improvement in the cleanliness of the manufacturing facility.

2. Enhanced Safety: With reduced dust levels, the safety of employees improved, minimizing the risk of accidents and injuries.

3. Environmental Impact: By controlling dust both indoors and outdoors, the facility contributed to a cleaner and healthier surrounding environment.

Cost & Efficiency:

1. Operational Cost Reduction: The mechanical floor sweepers proved to be a cost-effective solution compared to manual cleaning methods. The cost of labor to manually clean the vast amount of dust and debris was a greater multiple of expense versus the cost of renting the machines.

2. Time Efficiency: The efficiency of the floor sweepers allowed for quicker cleaning, minimizing downtime, optimizing production, creating a safer environment, and increases employee morale by having a clean workspace.

3. Capital Savings: Faced with challenges posed by year end budgeting and capital constraints, the company pursued a strategic shift, opting for equipment rental over traditional capital expenditure. This choice resulted in noteworthy cost savings, allowing immediate access to new, high quality equipment, without the immediate financial strain of upfront expenses.

Conclusion

The integration of walk-behind and ride-on floor sweepers revolutionized The Facility’s approach to cleanliness and safety. By addressing dust-related challenges, the company not only improved the working conditions for its employees but also demonstrated a commitment to environmental responsibility. This case study highlights the positive impact of our floor sweepers in industrial settings, showcasing a successful collaboration in achieving cleaner, safer, and more efficient manufacturing facilities.

Miles Davidson

Director of Sales & Marketing / Allied Flooring Solutions